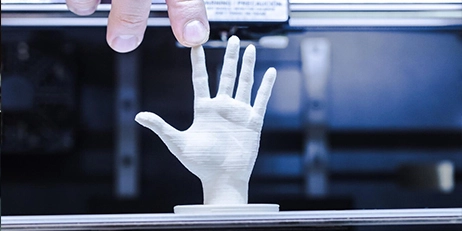

By reducing the cost of molds, 3D printing can reduce mold costs, reduce materials, reduce assembly, and shorten the R&D cycle. In the production process, the manufacturing cost of the enterprise can be reduced, so can this manufacturing and processing method also save costs?

1. Design optimization of industrial 3D printers

Precision 3D printing follows many principles similar to injection molding, such as gradual changes between adjacent surfaces; preventing large distances between part cross-sectional areas and volumes; preventing sharp corners of residual stress on finished parts; unsupported thin-walled structures should not be too high, otherwise it will warp.

2. Industrial 3D printers abandon the traditional

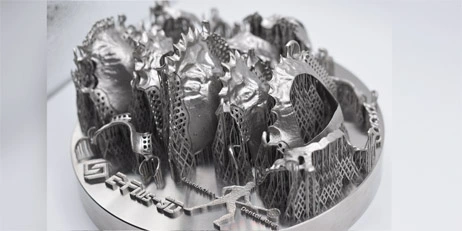

Common 3D printing technologies are biomimetic, such as honeycomb structures or complex point arrays. In terms of design, don't be afraid to choose this structure. If you can make lighter and stronger parts, you don't have to worry about choosing a hole structure in the design, because drilling invisible holes in the part with traditional manufacturing methods will increase material consumption and cost.

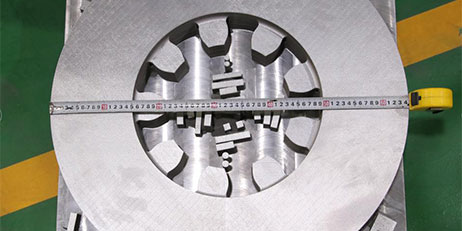

However, in additive manufacturing, especially when choosing laser melting metal to process round holes in industrial 3D printer equipment, it is necessary to consider whether to increase the support structure with holes and the possible deformation of the lower surface. Replacing round holes with teardrop or hexagonal hole structures is a better design approach.

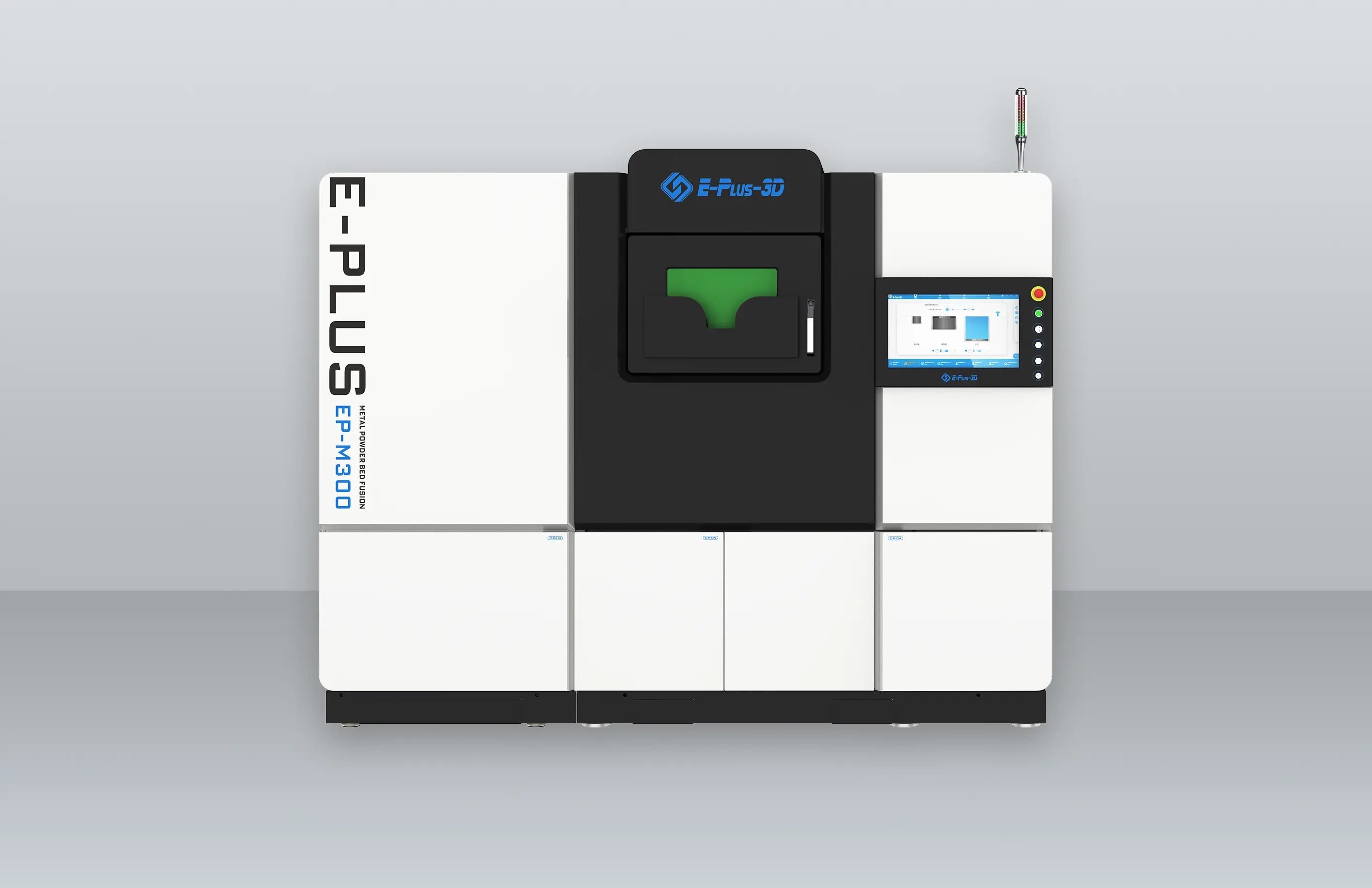

3. Industrial 3D printers consider how to manufacture parts in mass production

3D printer equipment can complete free modeling, which provides a lot of space for part design innovation. 3D printing can produce parts with many holes, but that doesn't mean the parts have to be designed that way.

The reason is that many companies realize that industrial 3D printers can be applied to small batch production of parts. However, when the number of products required by an enterprise increases significantly, it still needs to consider converting traditional processes into machining, casting, etc.

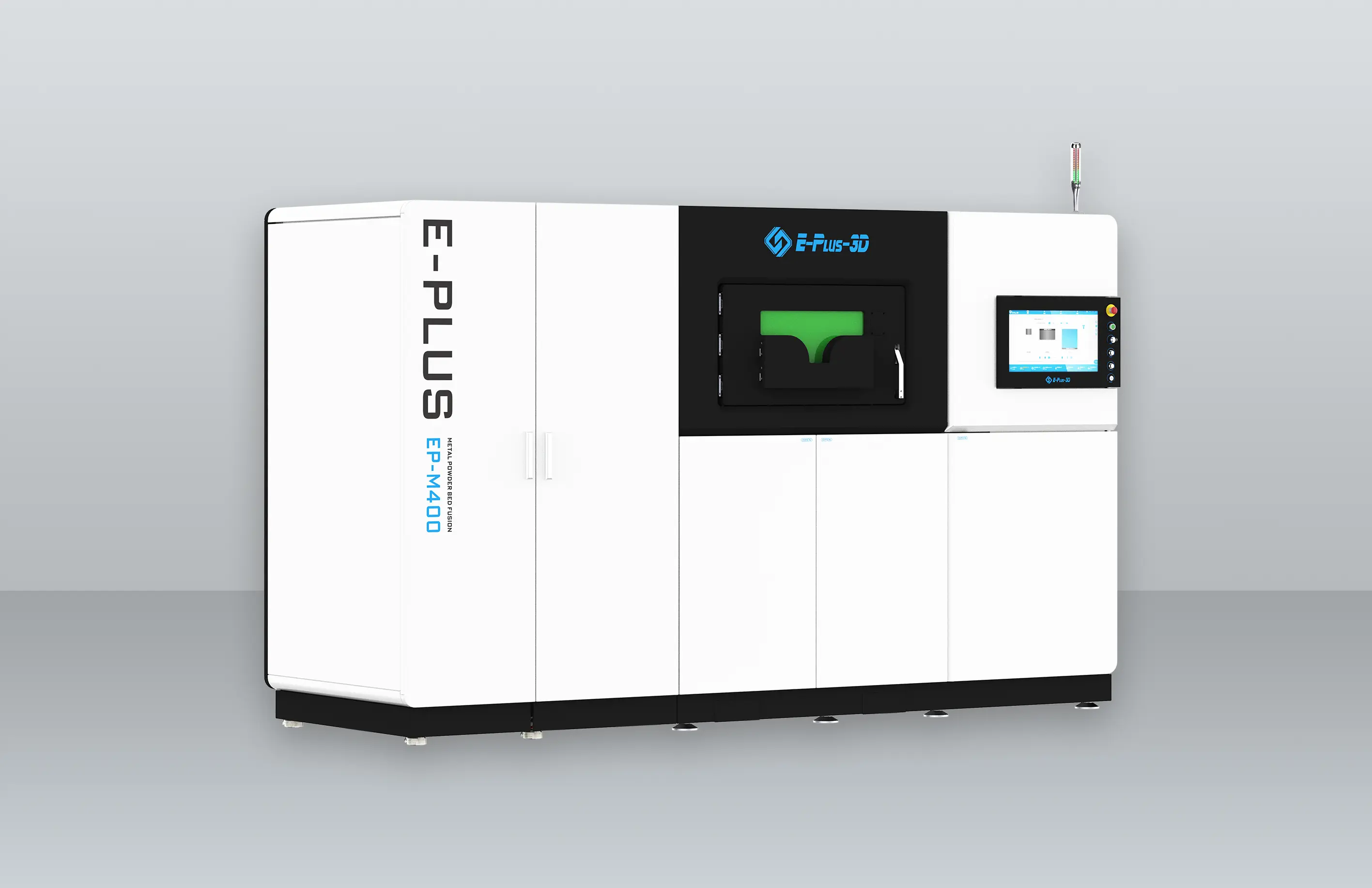

In this case, designers need to comprehensively consider whether the manufacturing process selected when mass producing parts in the future can also successfully complete the design in the early stage of design, and then measure it in the design.

Manufacturability analysis is critical in the early stages of the design cycle, enabling companies to complete low-cost, efficient production throughout the life cycle of components.

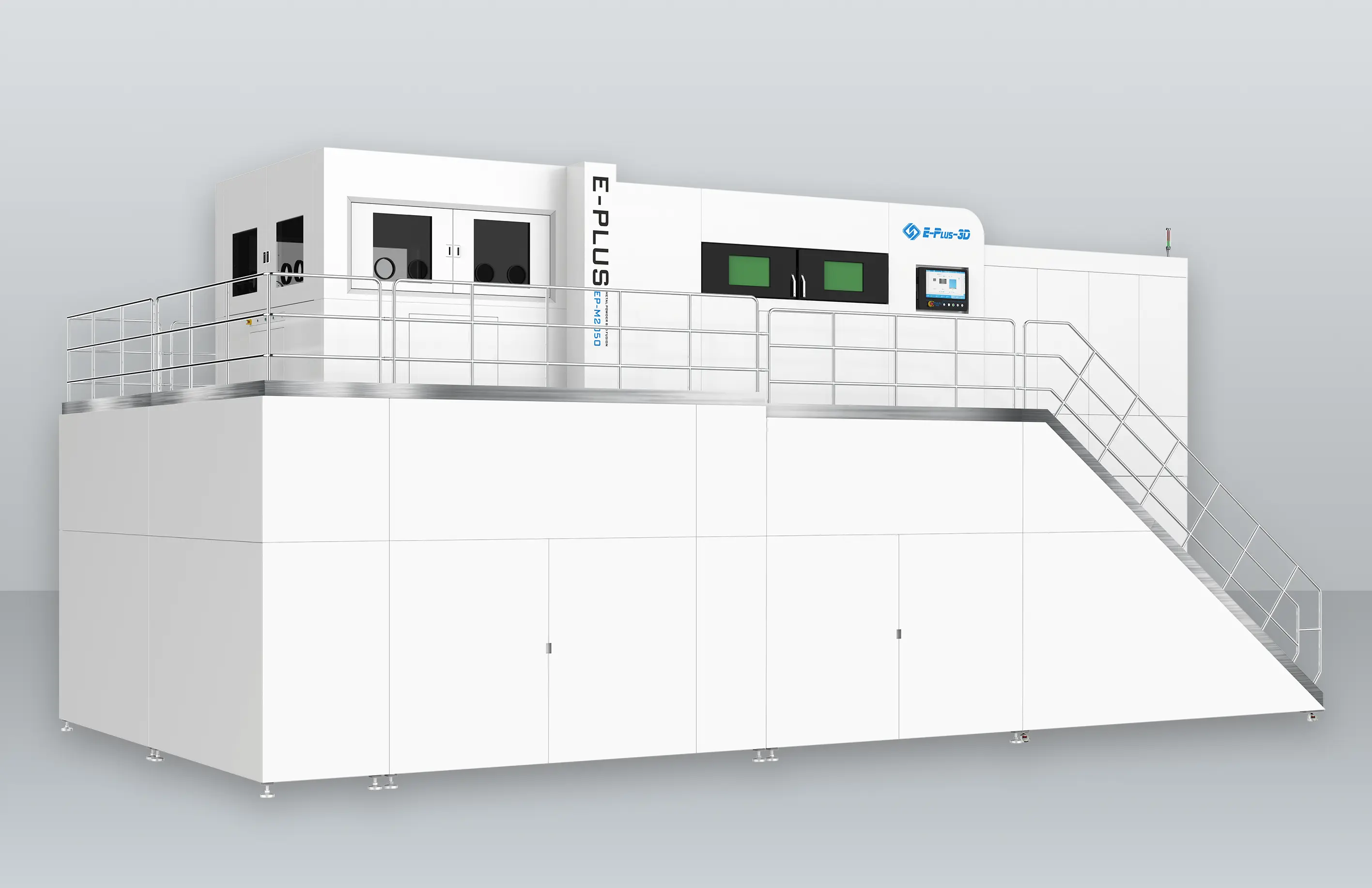

4. Industrial 3D printers are based on the overall situation

Although the cost of 3D printing materials is higher than that of mature traditional manufacturing processes, 3D printing technology cannot be left behind. It is more important to note that 3D printing technology is completing the advantages of lightweight structure and functional integration of parts, so that 3D can give full play to printing technology in part optimization design.