The exploration and colonization of the Moon, with its abundant resources, have become focal points for researchers and space agencies as humanity continues to expand its spacefaring capabilities. However, the high cost and logistical challenges associated with transporting construction materials from Earth to the Moon present significant obstacles. To address this, in-situ resource utilization (ISRU) combined with additive manufacturing (AM) technologies like 3D printing have emerged as promising solutions to facilitate sustainable lunar exploration and construction. (NASA,2024)

Researchers have been conducting studies using real lunar soil samples collected from past missions and various simulated lunar regolith types to explore the feasibility of using lunar regolith as a construction material. Utilizing these materials, NASA and other institutions have made significant progress in creating construction materials on the Moon, including concrete samples with high compressive strength. These studies have identified challenges such as the vaporization of water in lunar regolith-based materials due to vacuum conditions, affecting their constructability and mechanical performance.

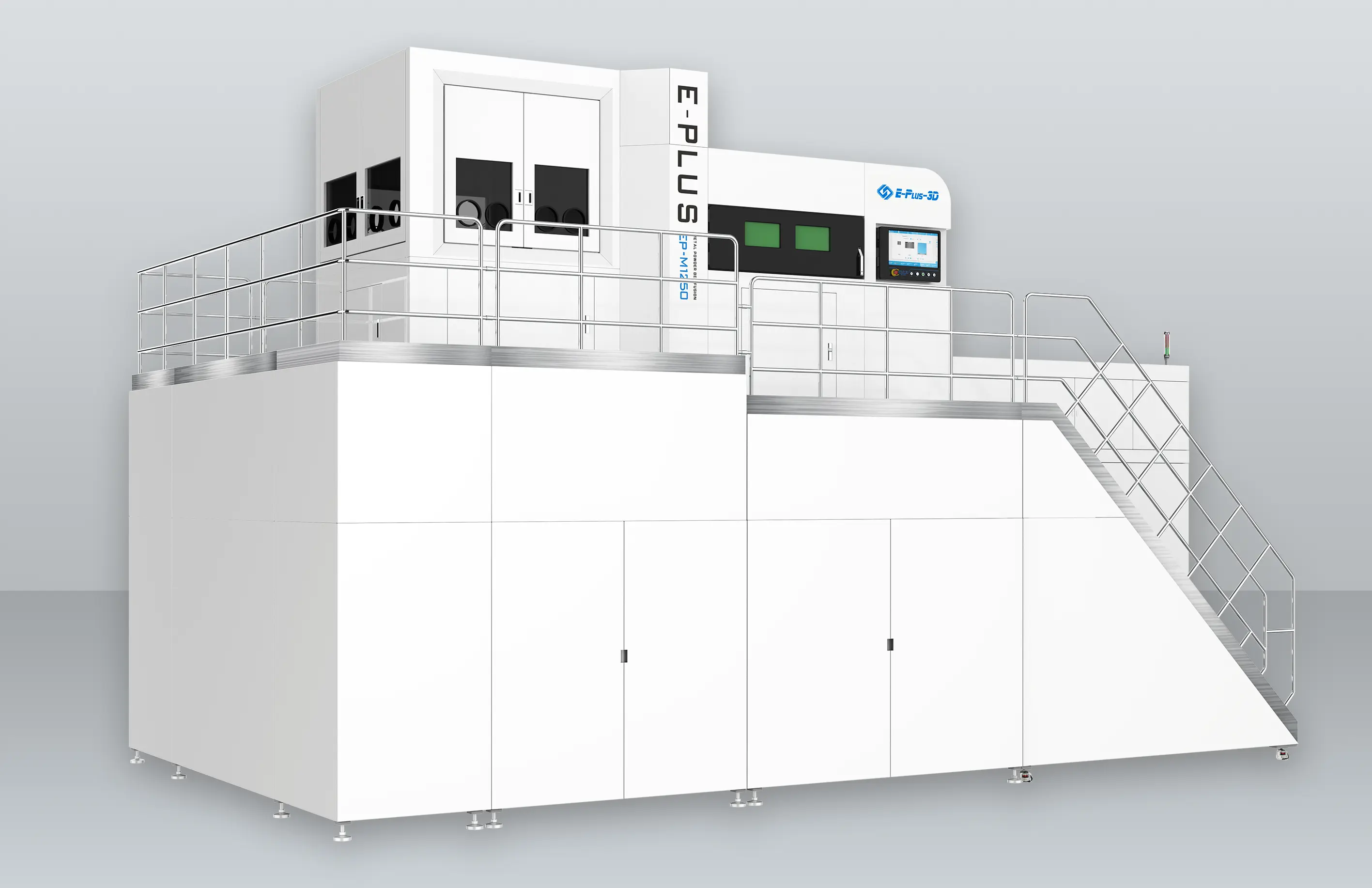

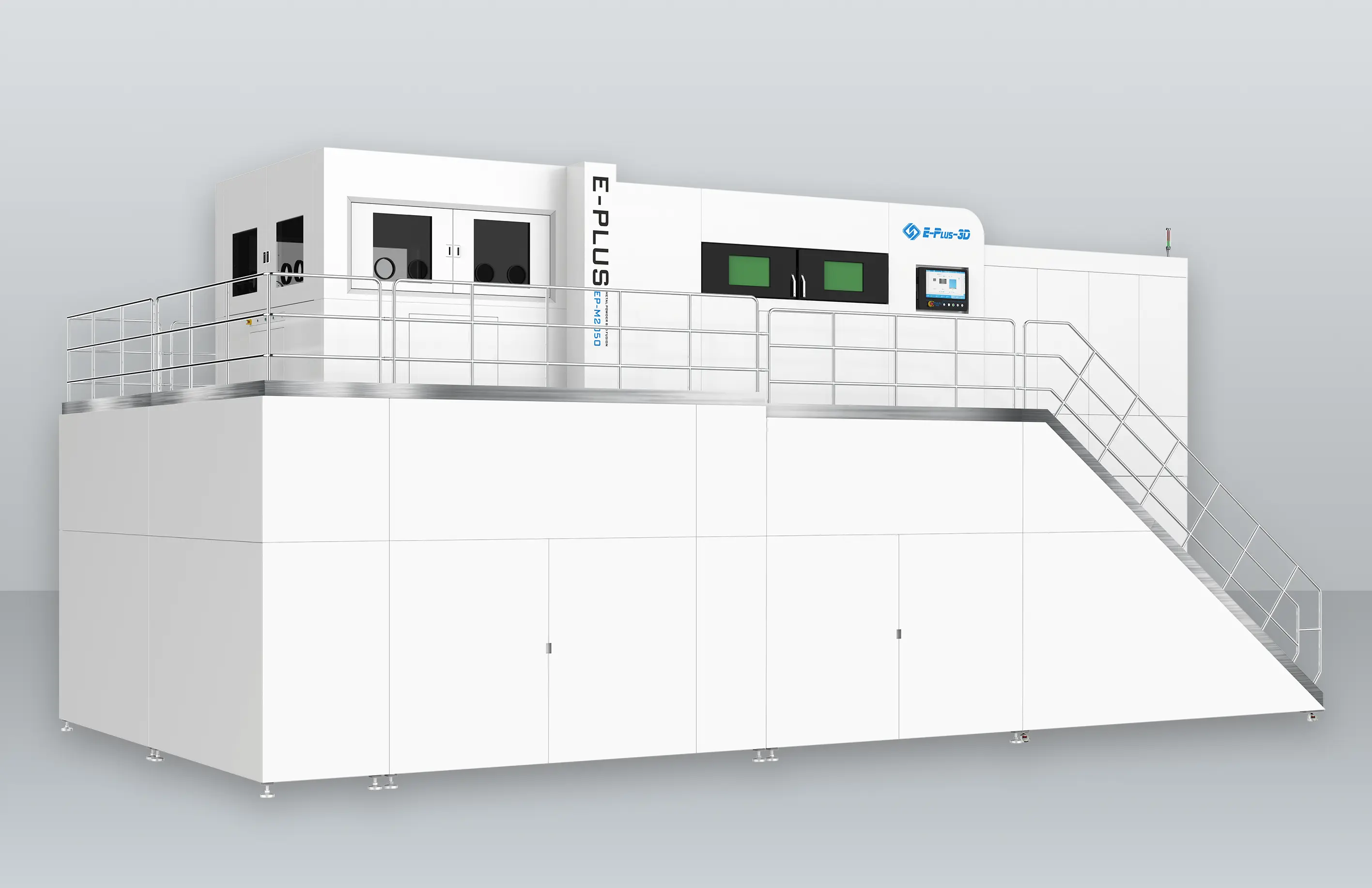

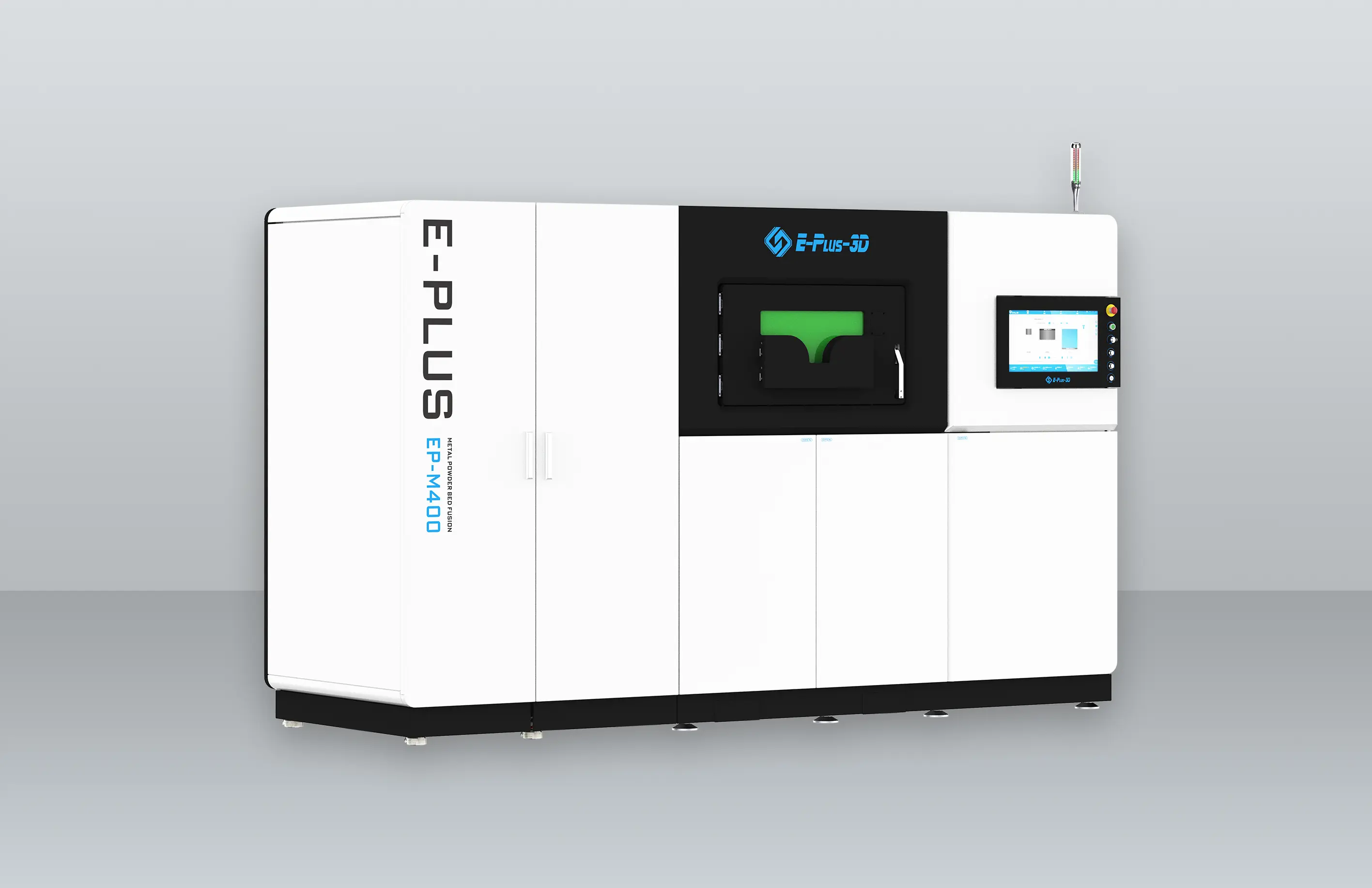

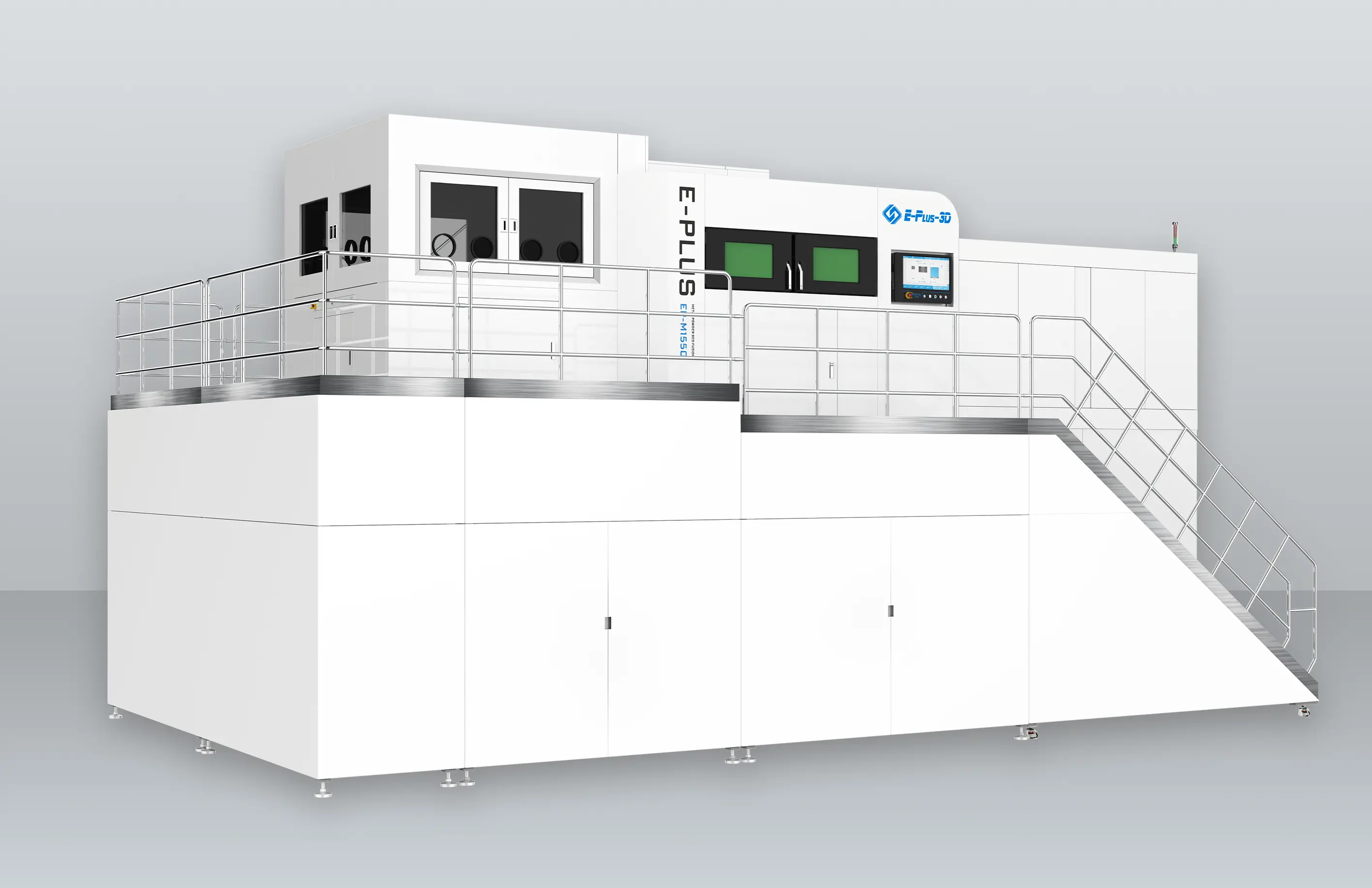

Recent research has focused on utilizing simulated lunar regolith for Selective Laser Melting (SLM) in additive manufacturing. The studies have demonstrated the feasibility of using SLM for lunar in-situ resource utilization, achieving a significant compressive strength with relative porosity ranging from 44% to 49%.(LIU et al.,2024)

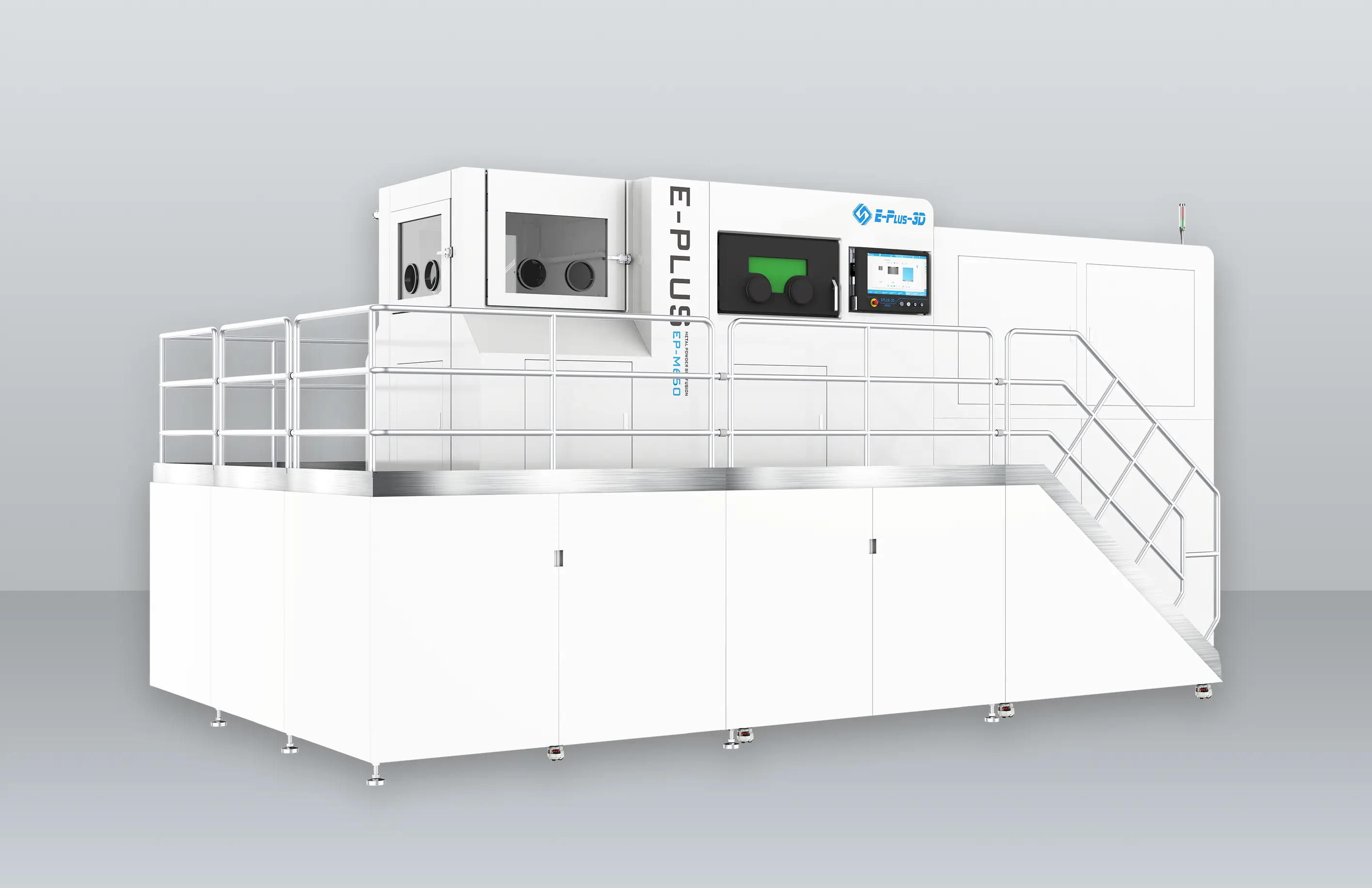

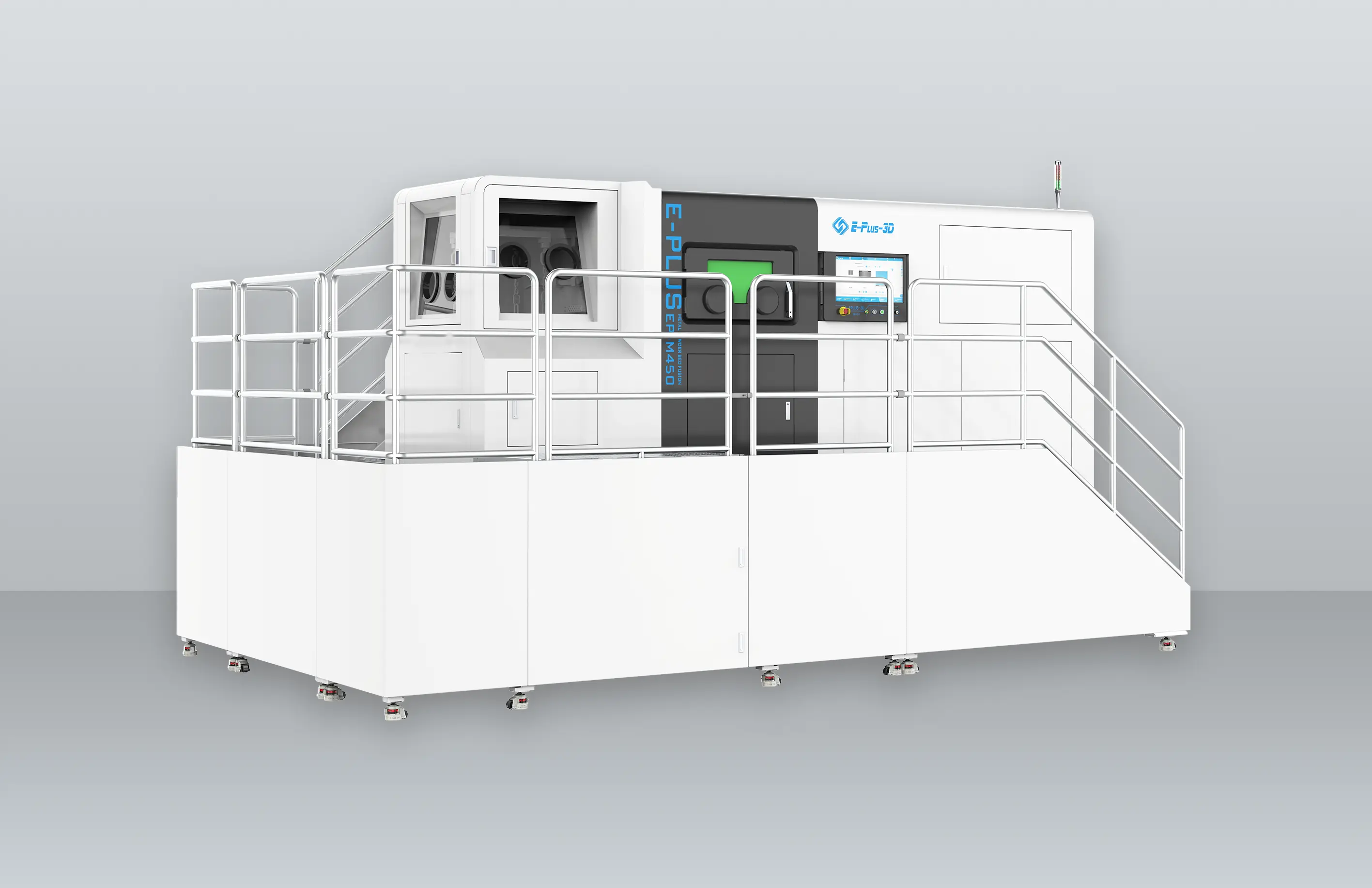

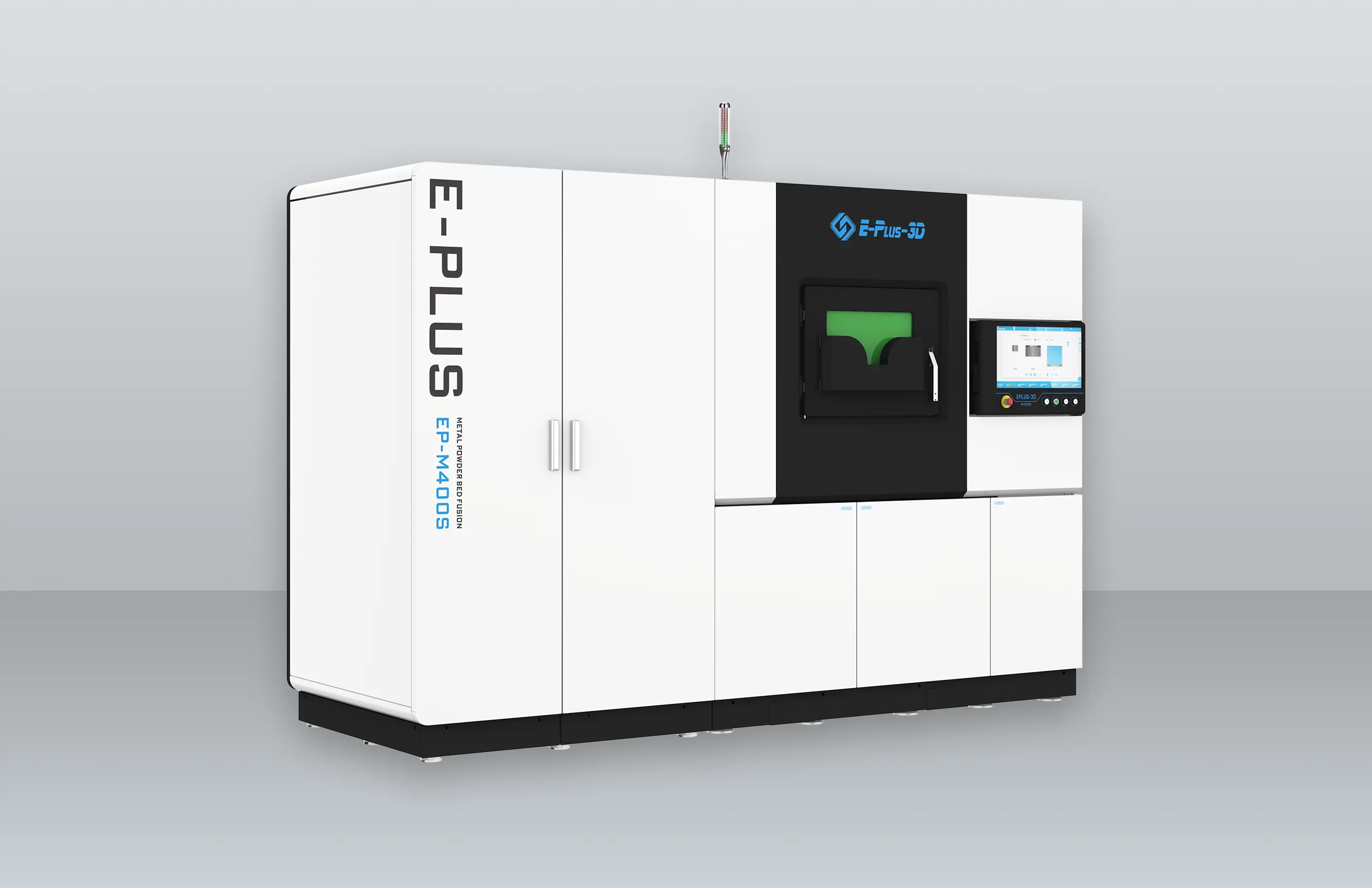

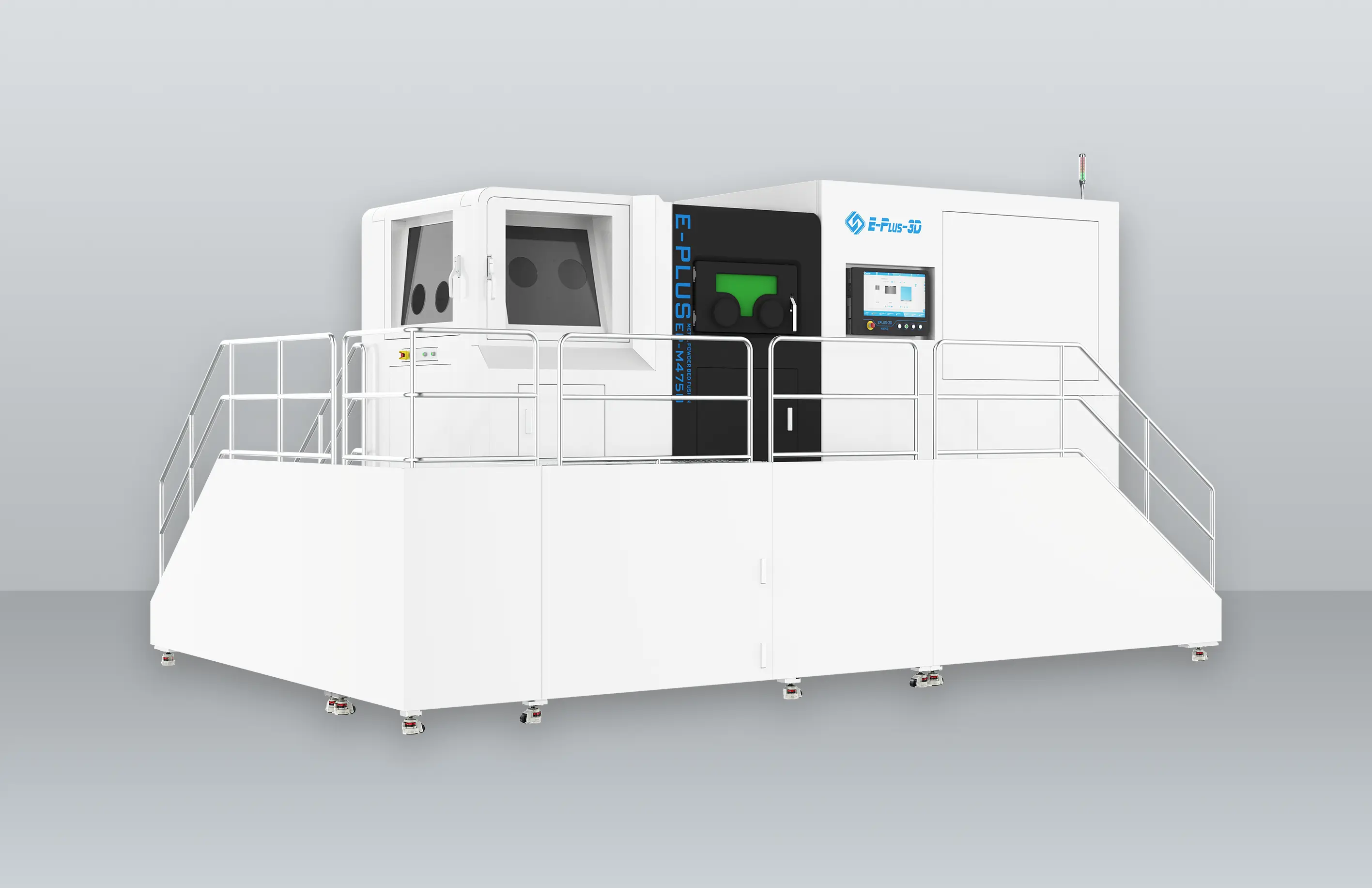

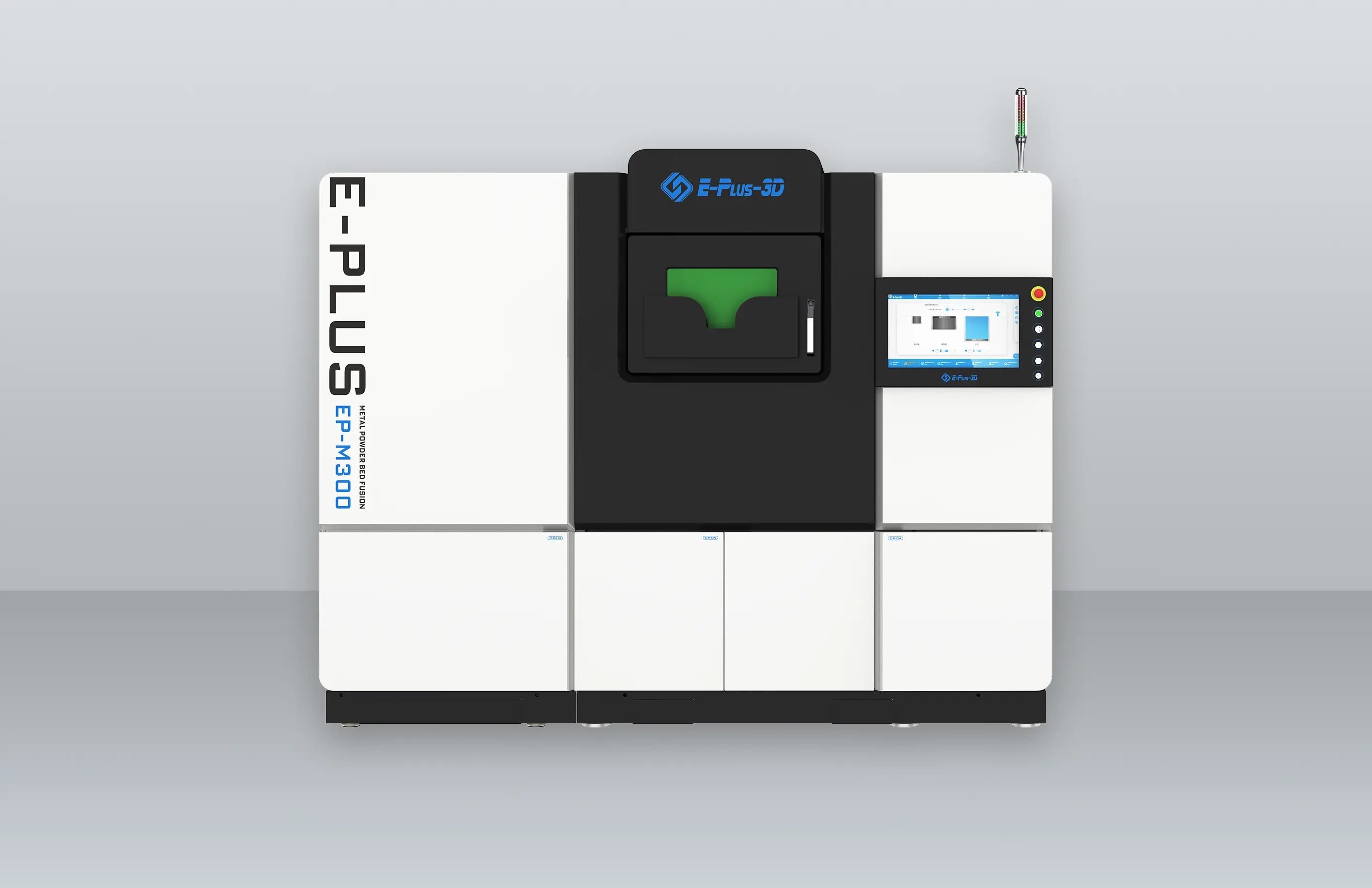

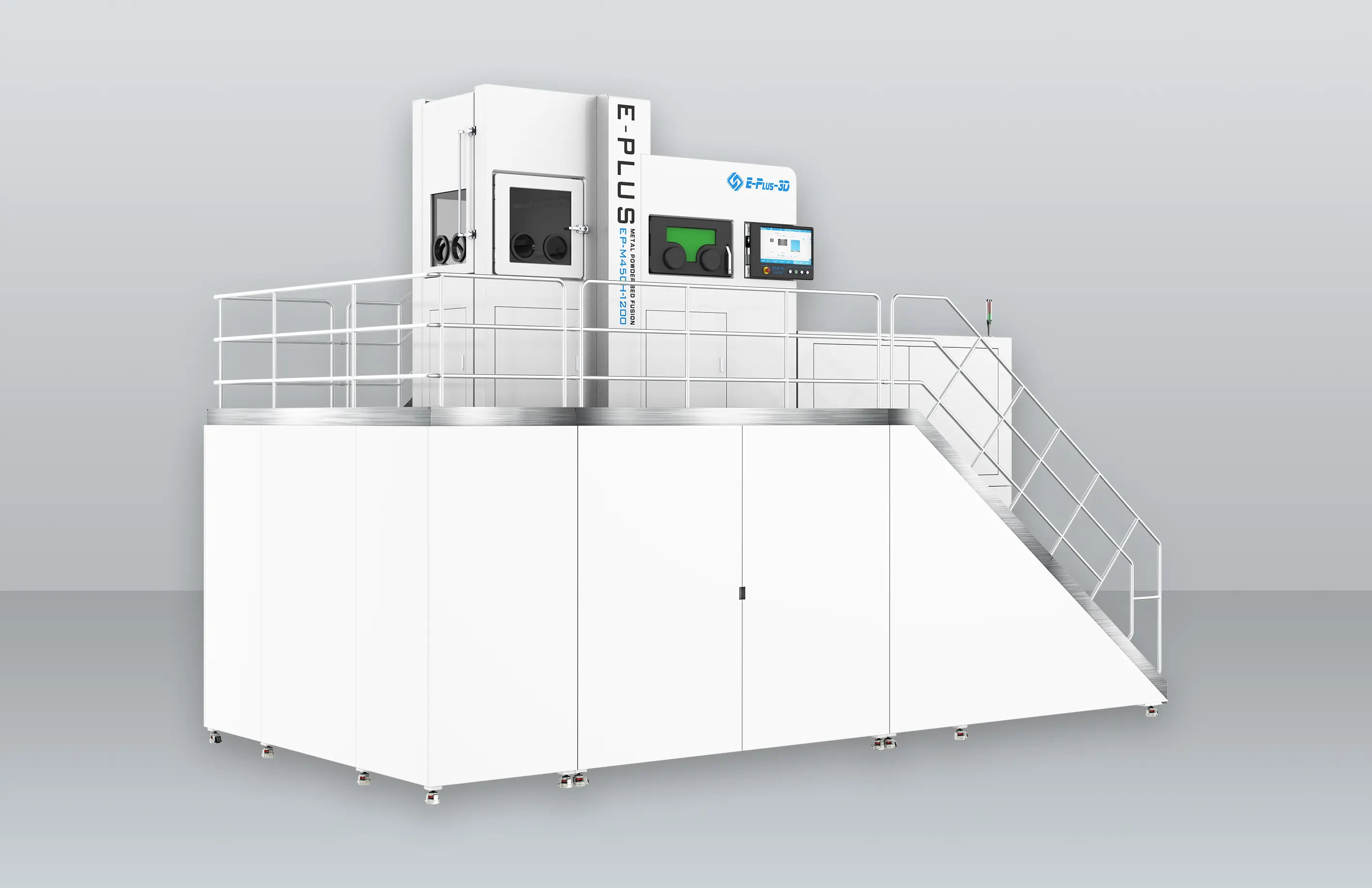

To further explore the potential of 3D printing with lunar regolith, a research team set up a Selective Laser Melting (SLM) experimental system using simulated lunar regolith material. The study aimed to investigate the impact of laser power, scanning speed, and initial powder layer thickness on the densification of printed samples. The research presented valuable insights into the factors influencing sample densification, with relative density of 86% and excellent pressure resistence, providing crucial support for in-situ construction technologies. (LIU et al.,2024)

Through the exploration of lunar regolith as a construction material for in-situ 3D printing and the development of innovative 3D printing technologies for lunar construction, humanity is taking a significant step towards realizing long-term lunar exploration and colonization goals. These advancements have the potential to revolutionize space construction while facilitating sustainable and cost-effective lunar base development.

reference:

NASA. (n.d.). Regolith-polymer 3D printing. NASA. (2024, January 4). January 10, 2024, https://technology.nasa.gov/patent/KSC-TOPS-88

LIU, Y. W., ZHANG, X., & WANG, C. (n.d.). 3D printing densification of lunar regolith simulant[J].Chinese Space Science and Technology. January 10, 2024,