Metal 3D printing nowadays is a great complement in injection molding. 3D digitizing and printing allows for design and manufacturing molds with complex conformal cooling channel. This can reduce scrap, improve quality of parts and increase the cooling efficiency. Eplus3D provides a complete solution from 3D design to 3D printing for molding applications, dramatically increasing productivity.

Metal 3D printing VS. Traditional mold manufacturing

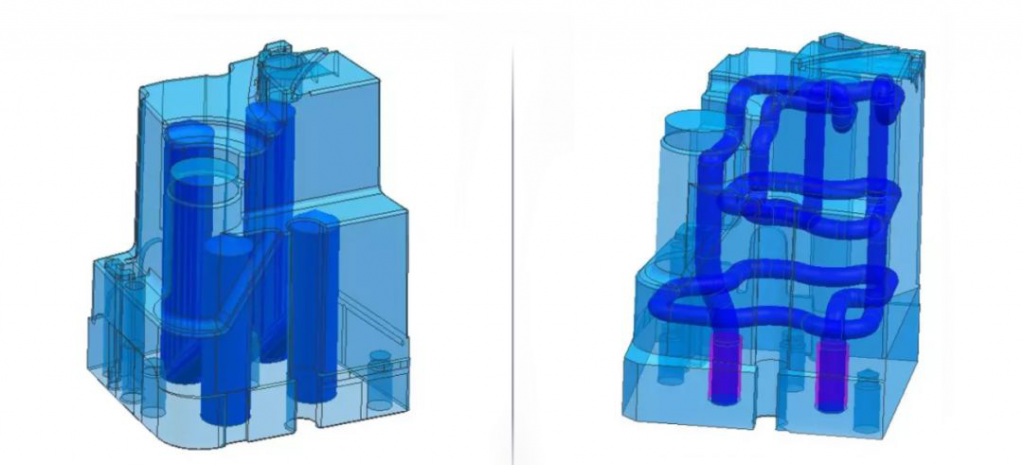

Traditional cooling channels /Conformal cooling channels

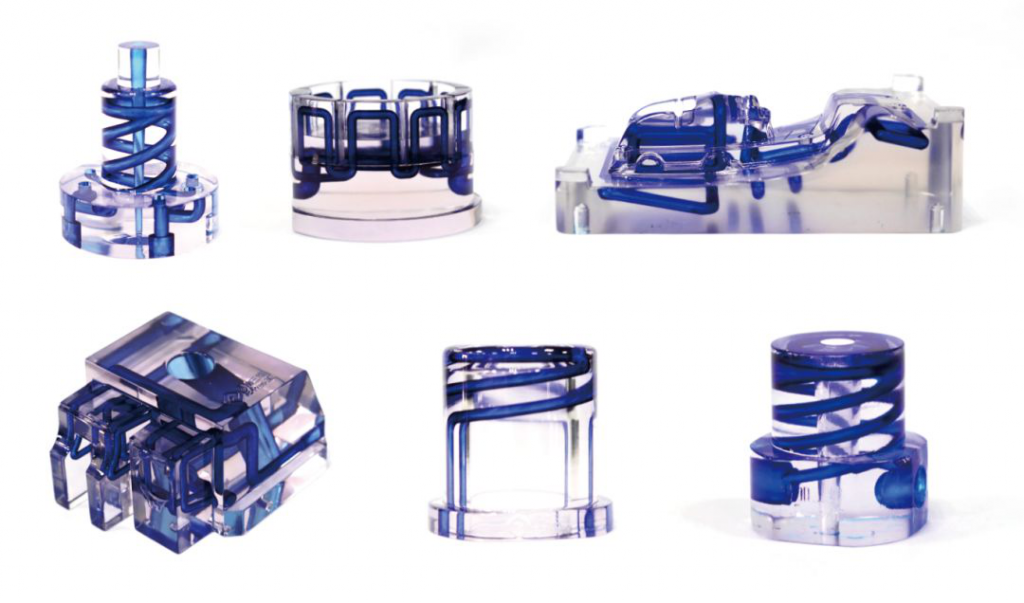

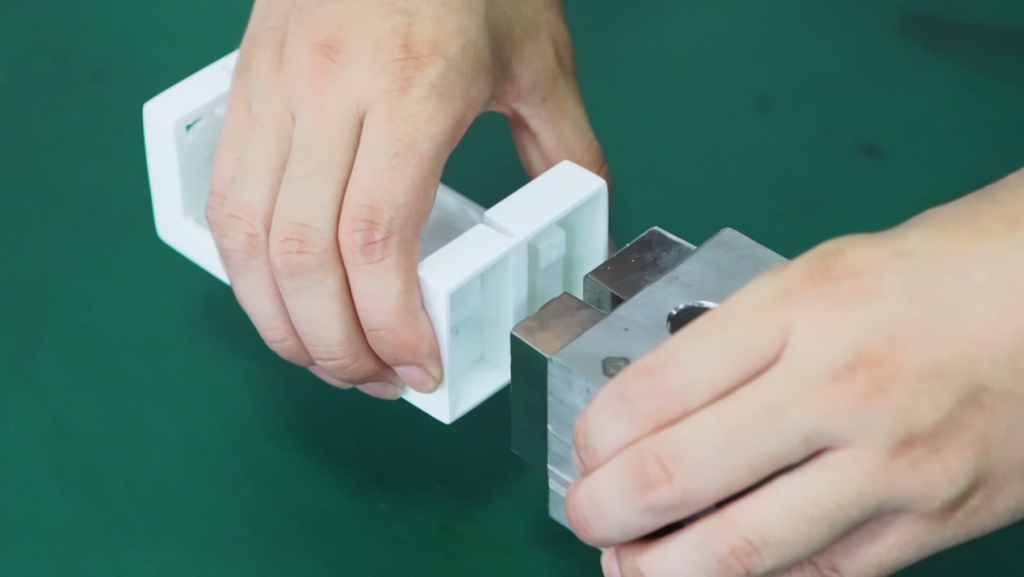

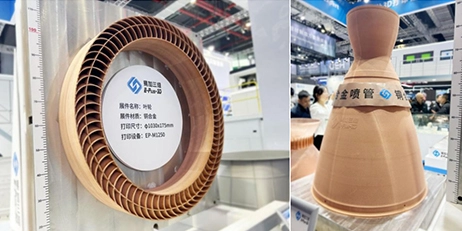

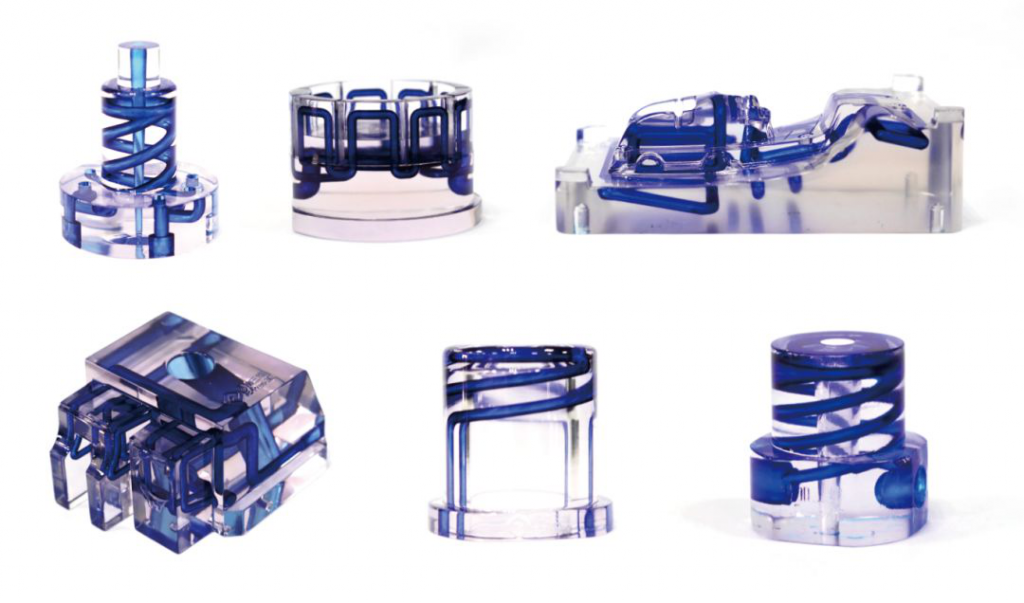

In the production of traditional molds, drilling can only produce straight waterways, which means that the shape of the waterway is limited and far from the surface of the mold. While 3D printing enables precise complex lattice and waterway construction. Designed in CAD software, the distribution of waterway is based on the geometry of the parts.

Compared to the traditional mold, 3d printed mold with conformal cooling channels have a higher heat dissipation efficiency, shortening production cycle and improving production efficiency.

The parts are often easily bent and deformed due to the high temperature in traditional manufacturing. With the uniform hear dissipation of the waterway, the 3d printer mold can manufacture zero-defective products, effectively improve product quality and reduce scrap.

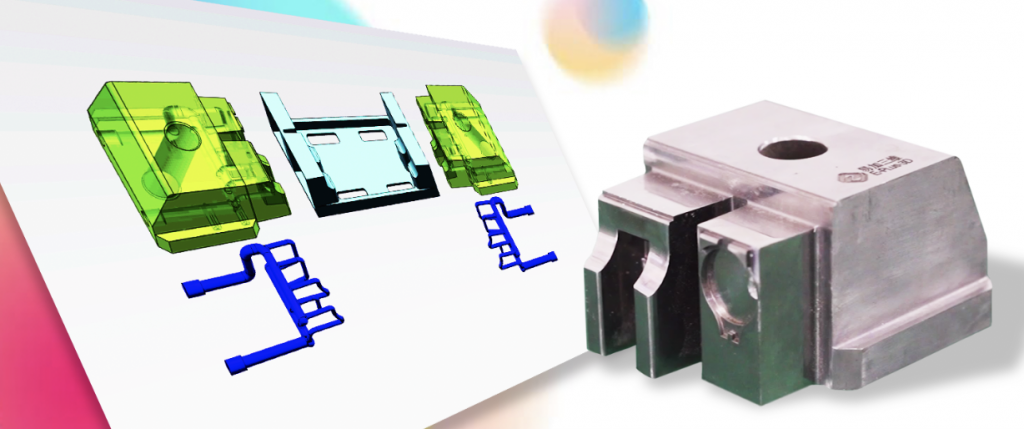

3D digitizing and 3D printing enable a lightweight construction of the mold and reduce costs. At the same, bridging mold can be design and manufactured based on the existing mold through 3D digitizing and printing technologies.

Workflow:

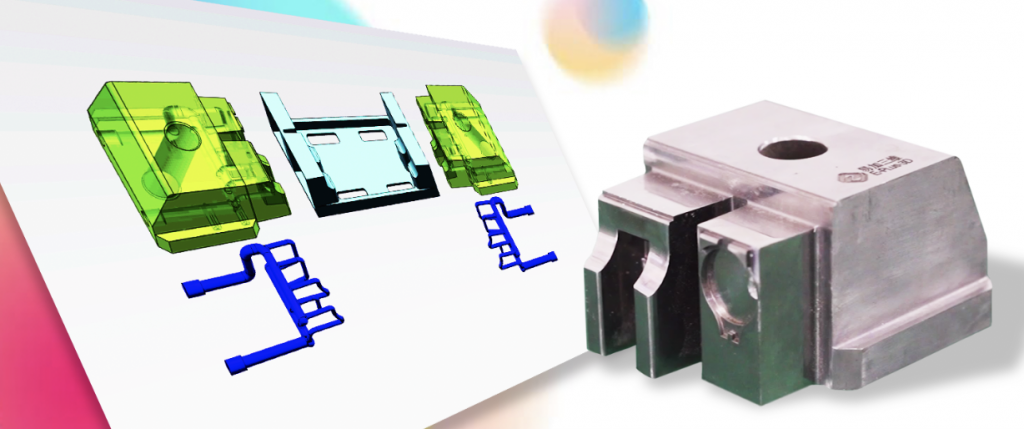

Mold design

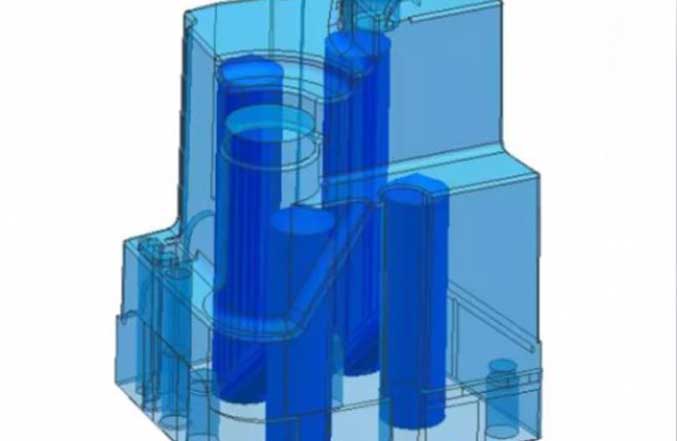

CAD design mold in SIEMENS NX software.

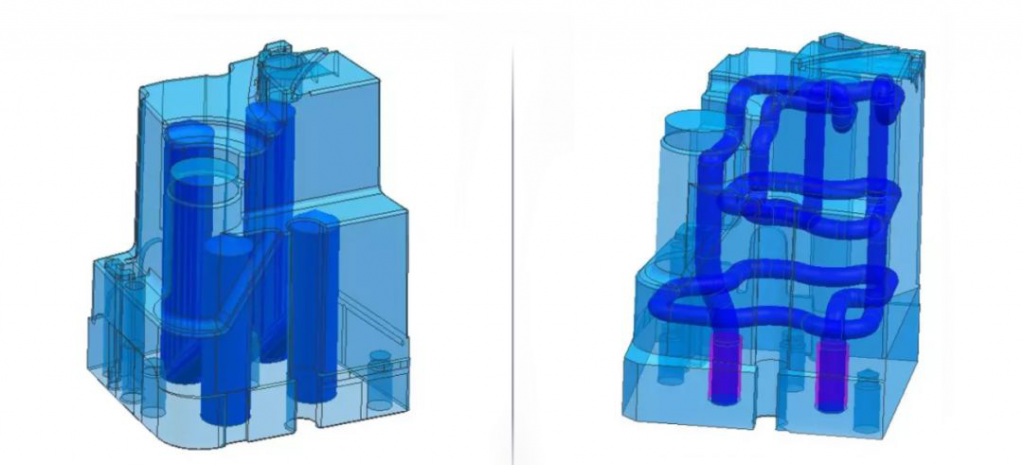

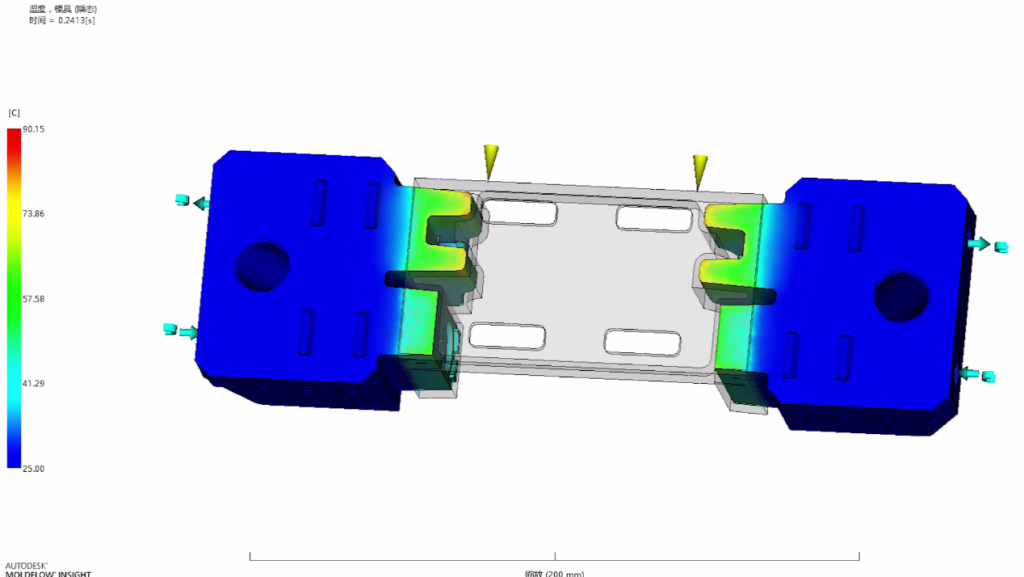

Simulation

Using NX’s simulation module to generate the analysis of molds’ waterway scheme, simulation of temperate change in the mold cycle. Based the result, optimize the design.

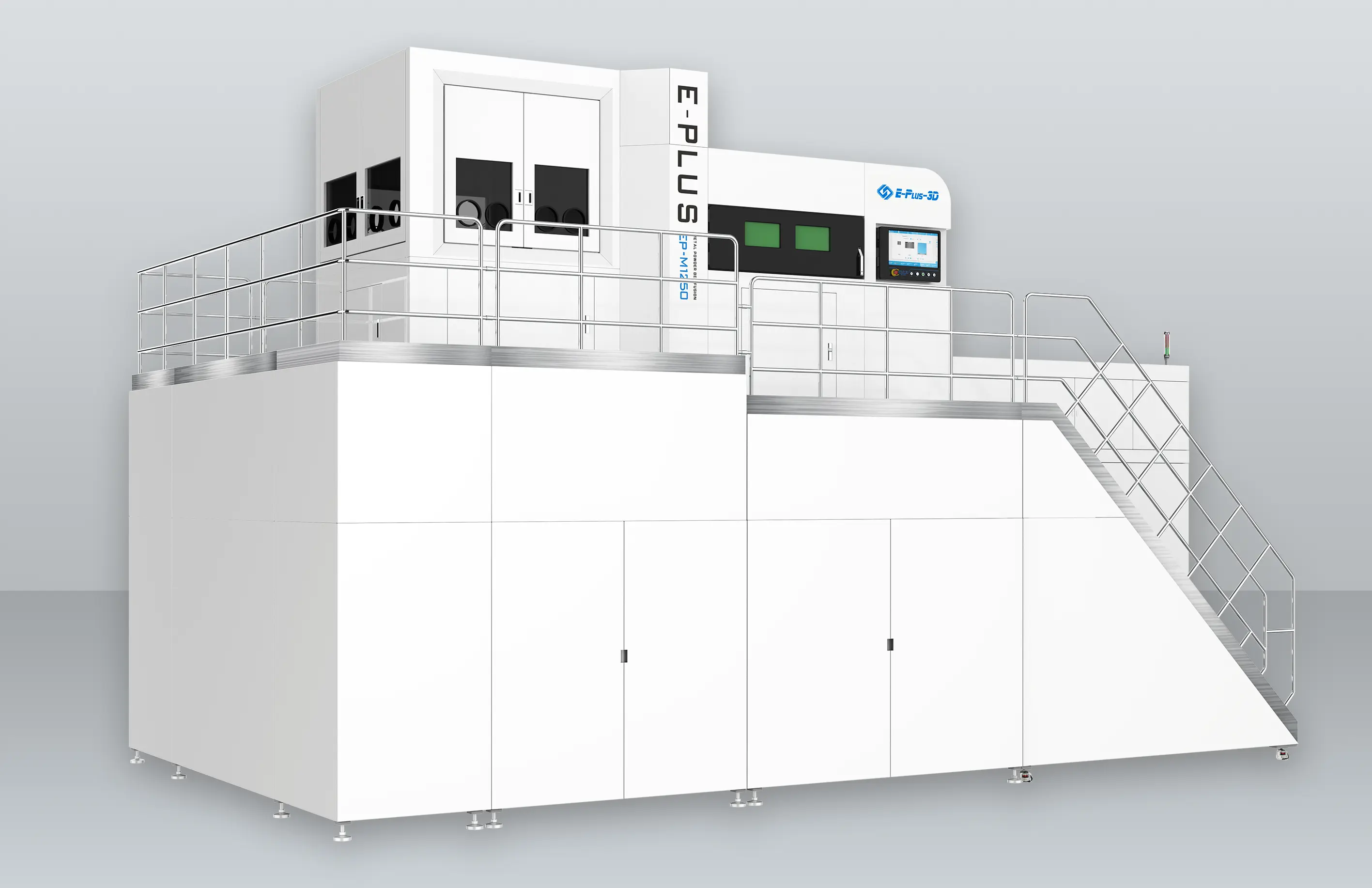

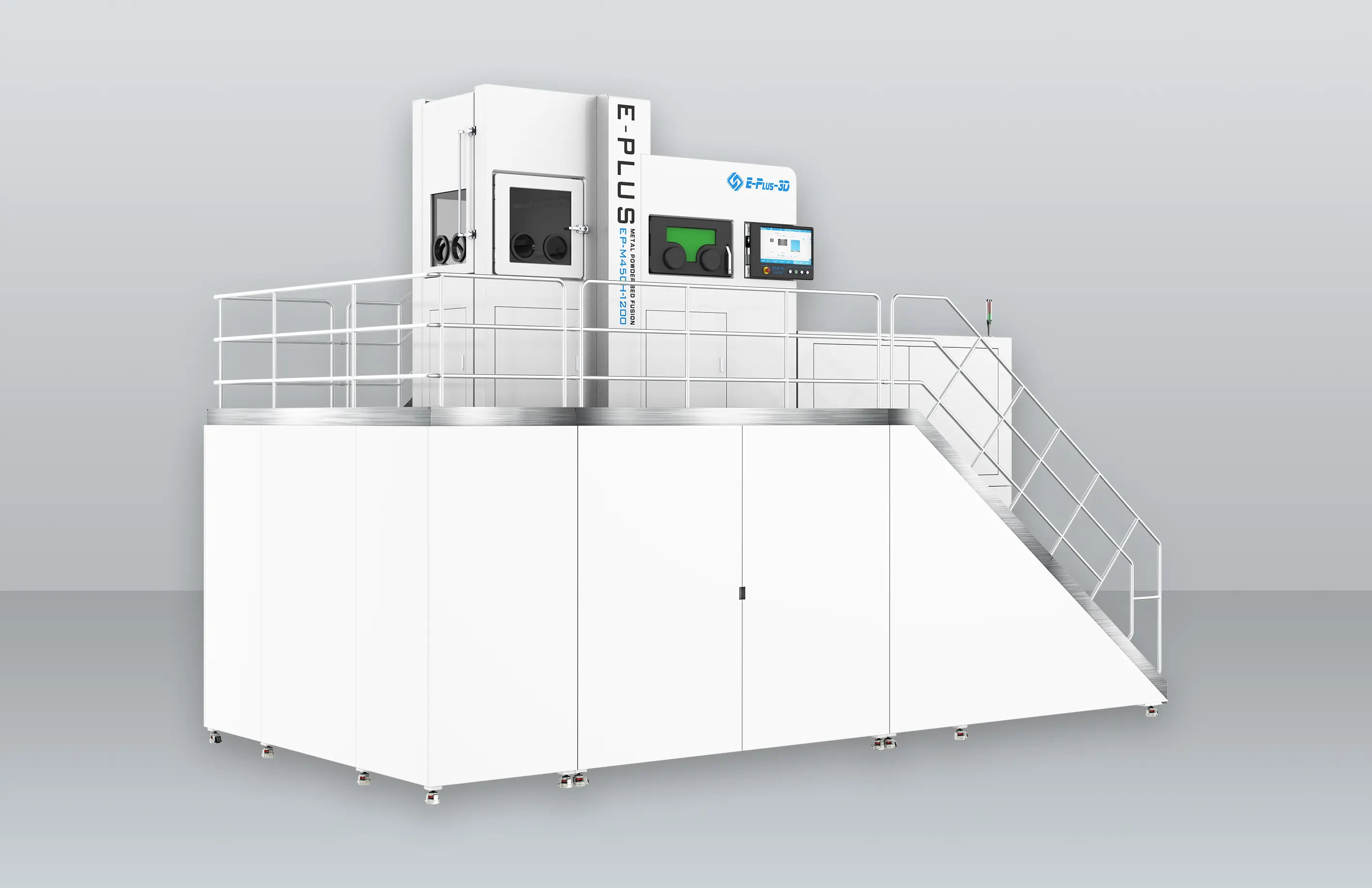

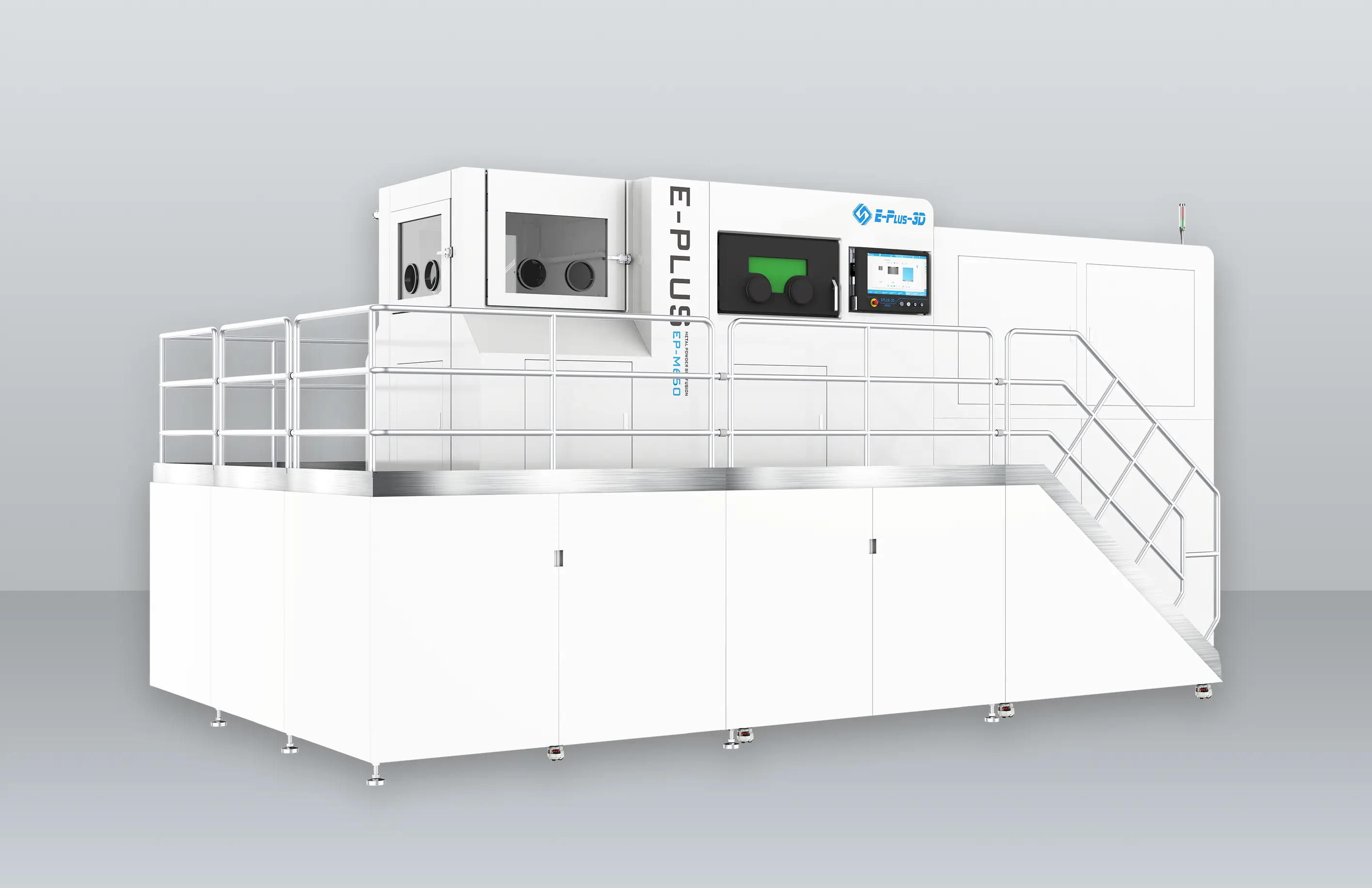

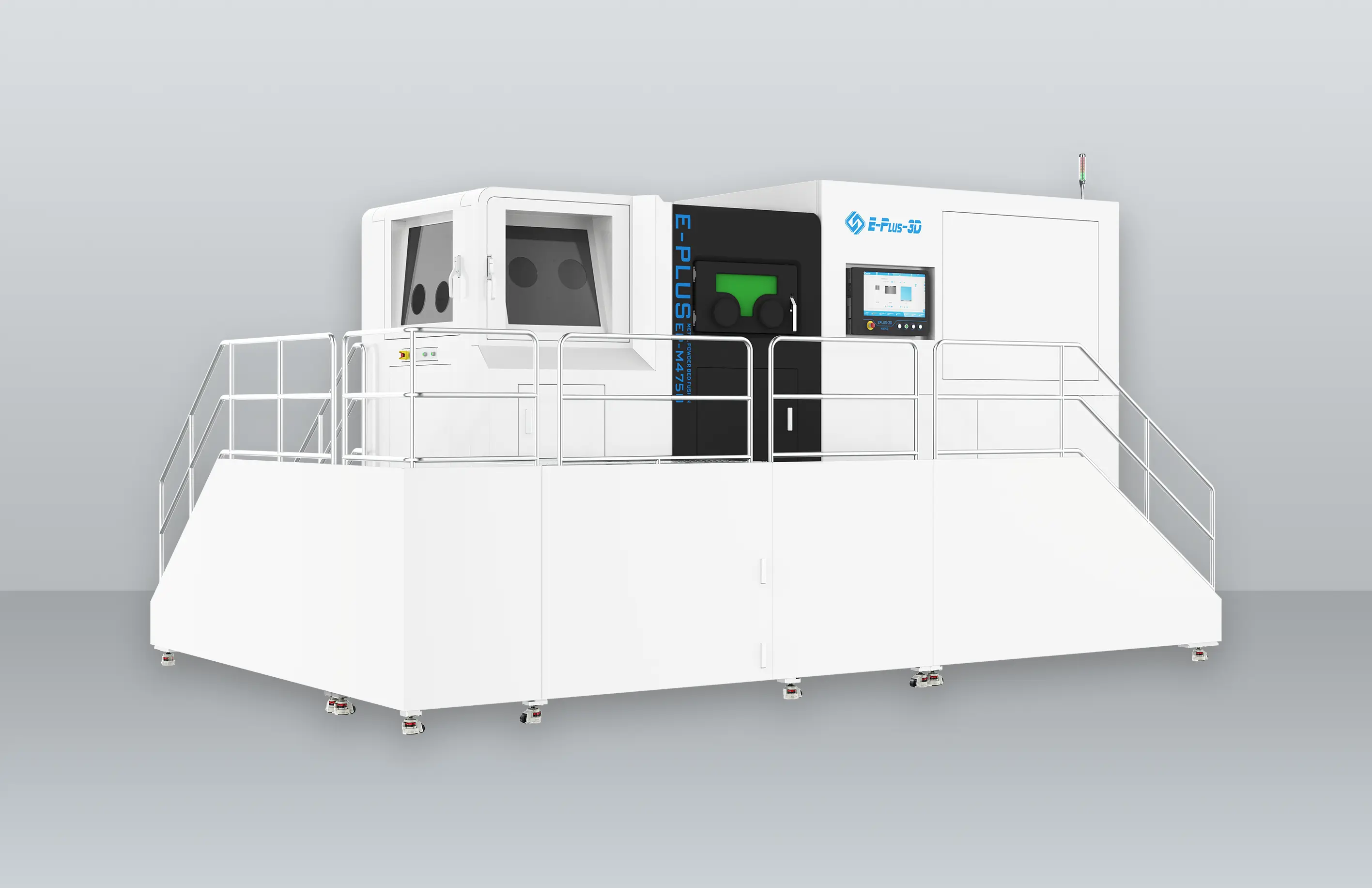

3D Printing

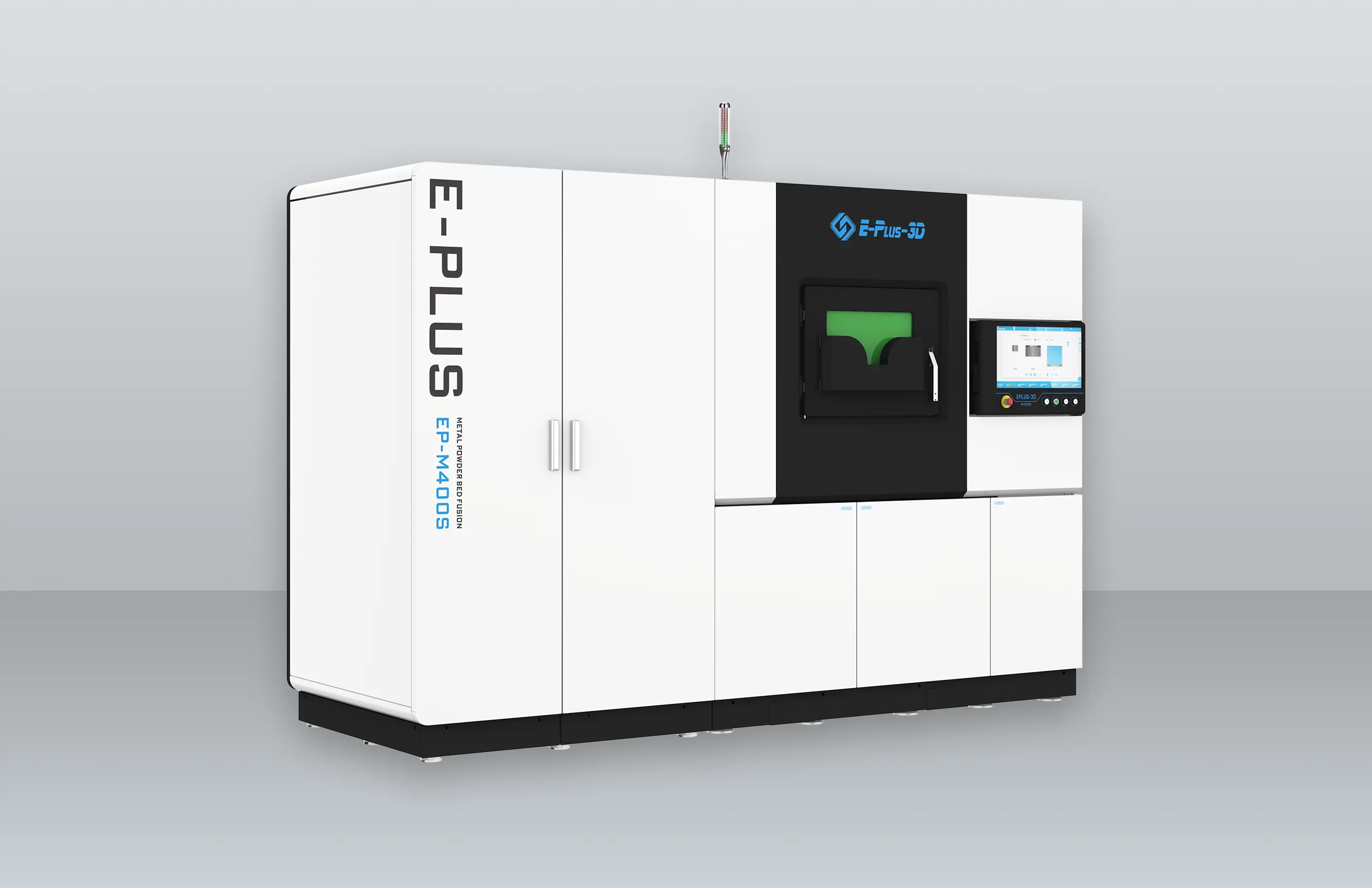

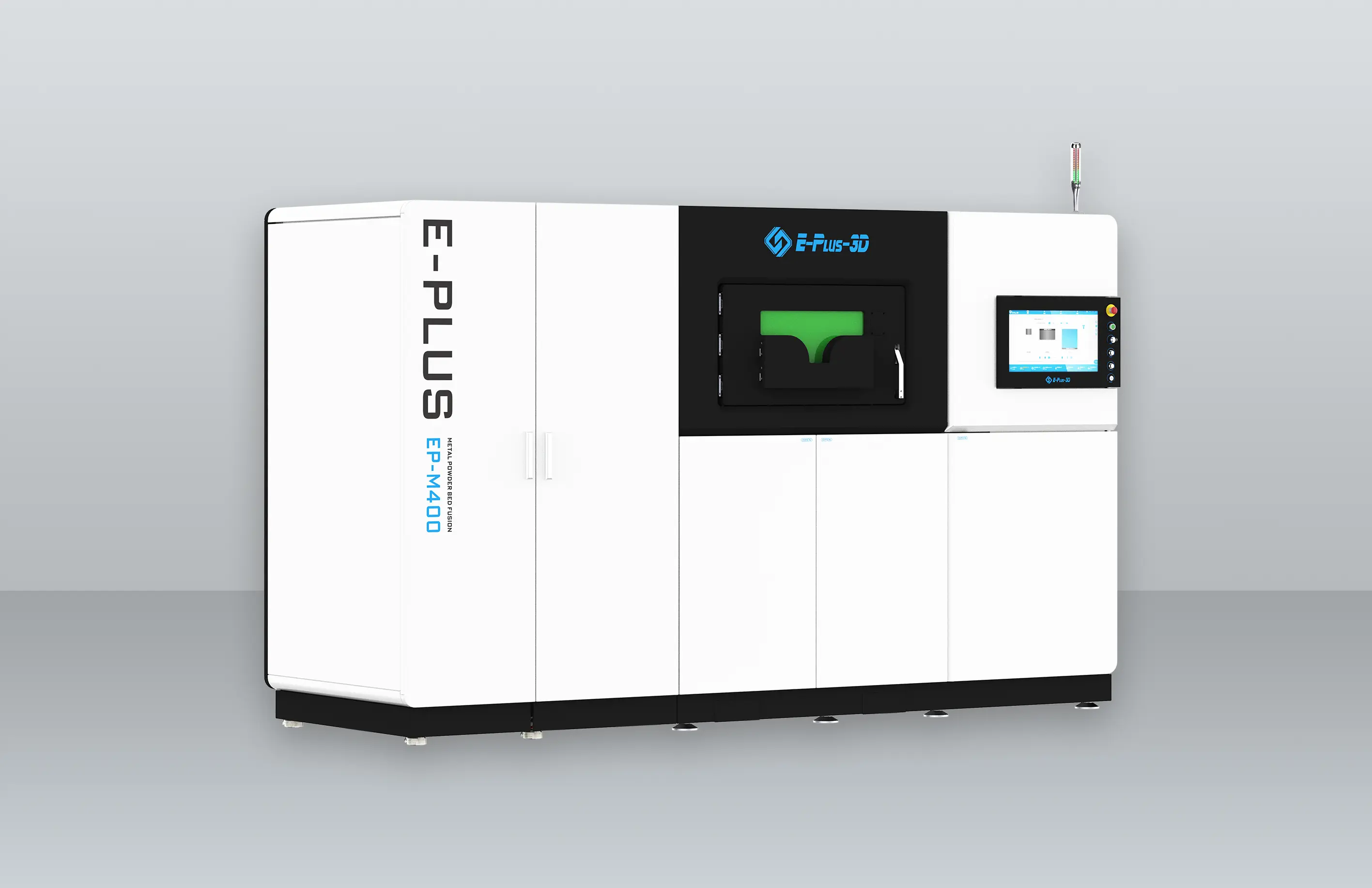

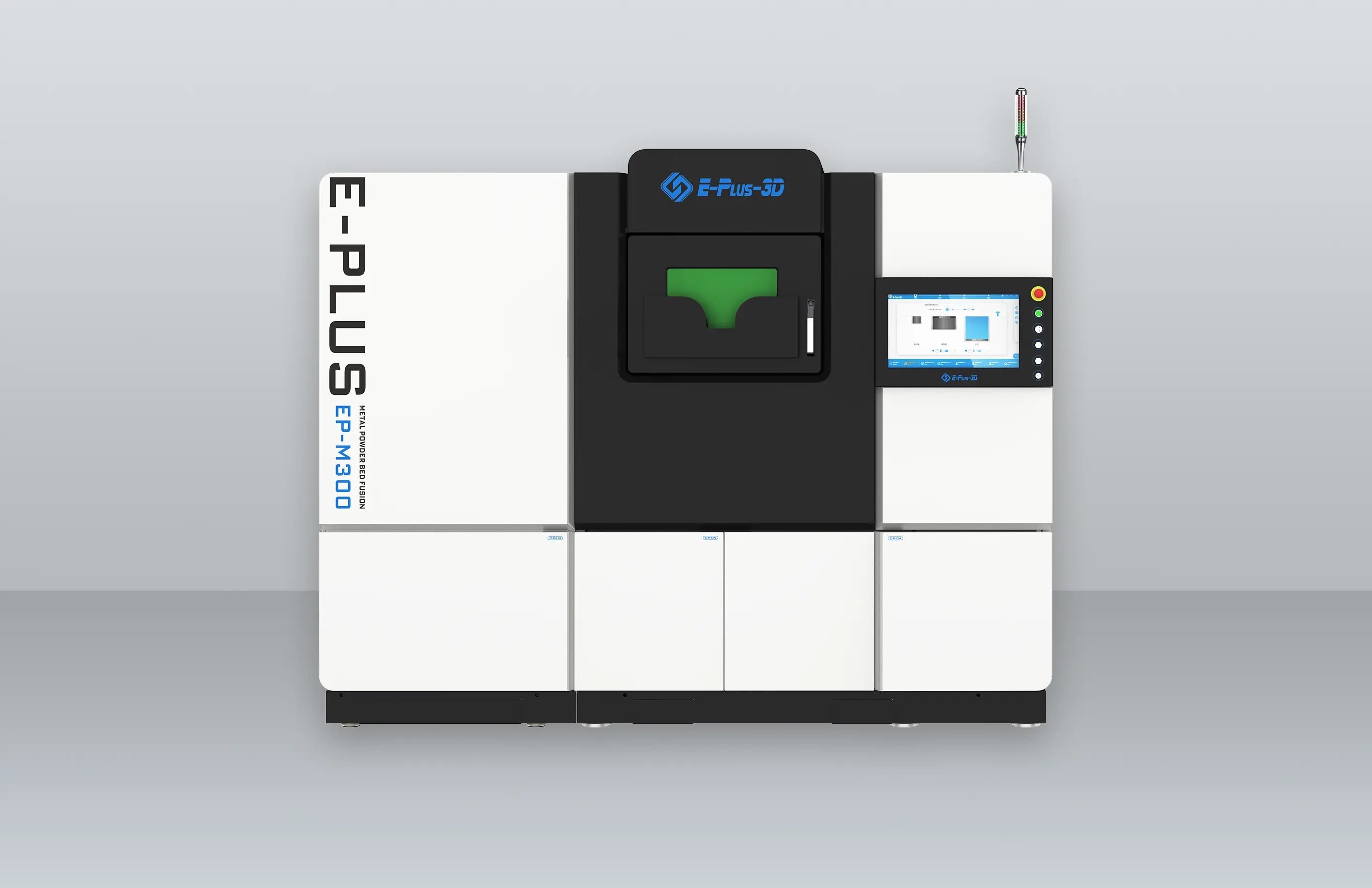

Using EP-M250 metal 3d printer, with up to 262*262*350 mm 3 building volume and high-precision printing, to manufacture high-quality the conformal cooling waterway molds

Metallographic analysis

Samples were taken for metallographic analysis to ensure that the print molds met quality standards.

Post-processing

Post-treatment such as heat treatment, de-support, surface treatment, etc.

Product Deliver

After the plastic product has cooled, remove it from the mold.

After the plastic product has cooled, remove it from the mold.

Not only in the field of injection molds, 3D printing also brings high-efficiency, low-loss, high-quality, individualized production modes for fields such as die-casting and stamping. With metal 3D printing technology and cost optimization, solutions from digital design to 3D printing are becoming more popular in the future and occupy a pivotal position in the manufacturing industry.After the plastic product has cooled, remove it from the mold.

After the plastic product has cooled, remove it from the mold.

Not only in the field of injection molds, 3D printing also brings high-efficiency, low-loss, high-quality, individualized production modes for fields such as die-casting and stamping. With metal 3D printing technology and cost optimization, solutions from digital design to 3D printing are becoming more popular in the future and occupy a pivotal position in the manufacturing industry.After the plastic product has cooled, remove it from the mold.